Over years of research and development, learning and R&D we have leveraged our material science knowledge of refractory metals.

Metal powder is the foundation of this process. We ensure the powder meets our stringent purity requirements and we make use of various complex grain structures and particle sizes as needed for unique customer applications.

Tungsten (Wolfram) and Molybdenum alloys of highest purity and desired particle sizes are used. We use special binding agents, emission enhancing coatings and impregnants to get the right density for the application need.

Our Porous tungsten is impregnated with standard emissive mixes of (BaO : CaO : Al2O3) 5:3:2 & 4:1:1 – other impregnates are also available.

Pre-mix Electrodes:

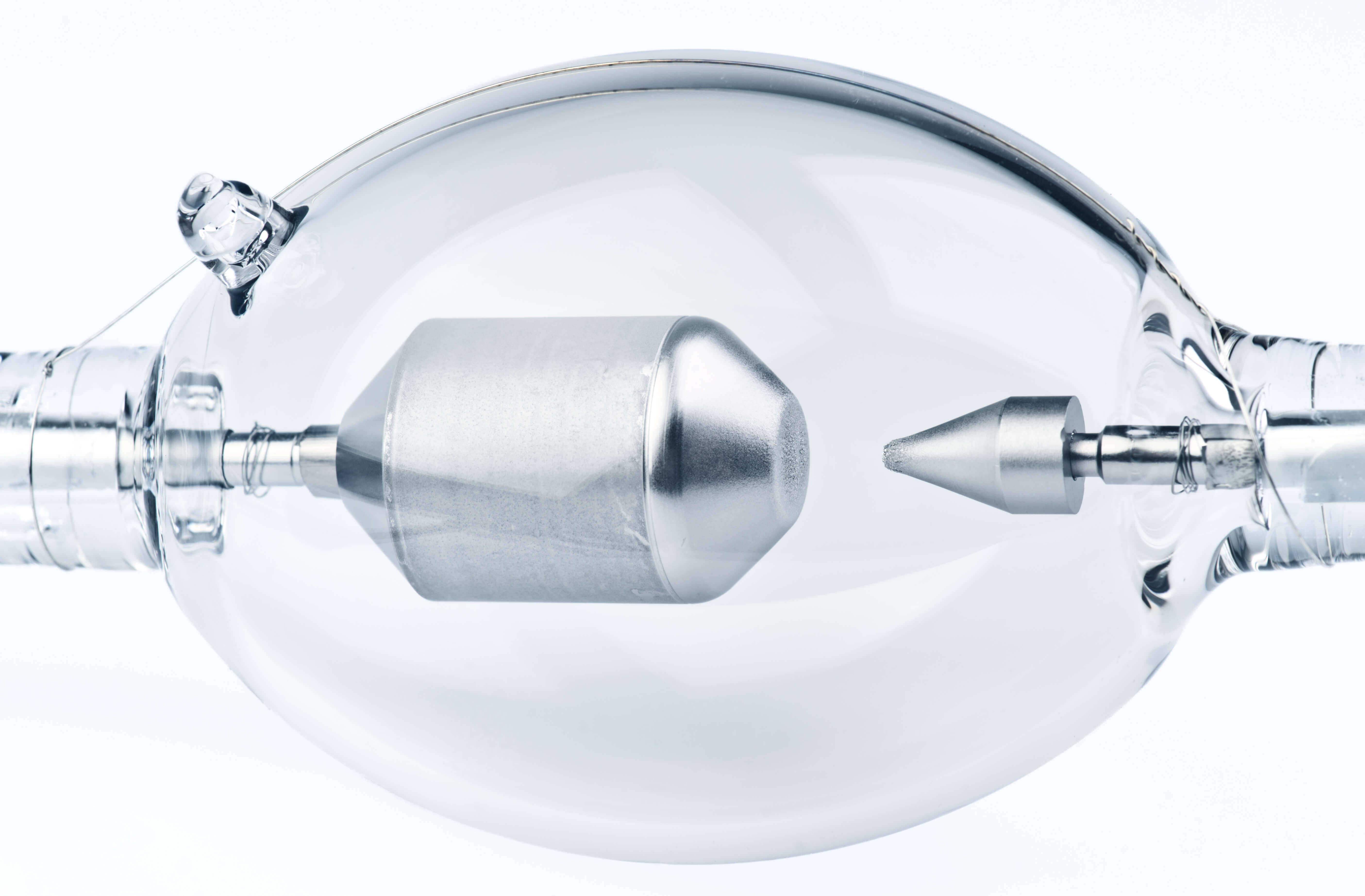

Over the years, we have developed special processes for making cathodes for high reliability product application needs such as Microwave Industry, Medical, Aerospace Industry, Defence Industry, CRTs, Laser Industry and Lamp Industry.

Various lamp applications such as xenon, krypton, flash Lamps, laser lamps, arc lamps use our cathodes.

We control each stage of the cathode manufacturing process, from basic powder raw materials to the manufacturing of critical components. We can customize tooling for special designs very economically.